- Home

- Factory visit

Factory visit

Workshop

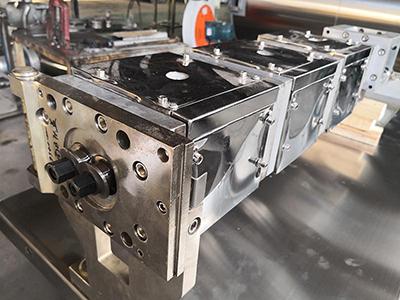

Saixin has two assembly workshops, one sheet-metal workshop and one warehouse. We can independently accomplish the processing of weld assembly and sheet-metal, installation of electrical control cabinet and assembly of equipment sets.

Team

Saixin was established in 1995. Our employees have over 20 years of working experiences. We have established SOPs and requirements for each step during production and assembly. The workers must conduct manufacturing and assembly strictly according to these requirements. Saixin has professional inspectors who can carry out strict audit and quality inspection of production process of each equipment and finished product.

Accessories

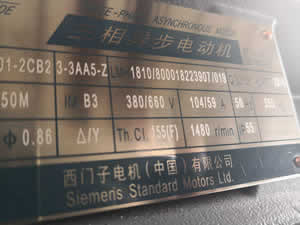

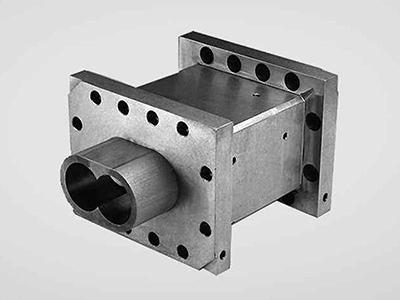

The electric devices such as motor, frequency converter, relay, contactor (switch) and temperature control instrument are selected from the internationally famous brands such as Schneider, Omron, ABB, Siemens etc. The bearing of the equipment adopts bearing pack which has strong carrying capacity. The extruder adopts building block system screw assembly which is made of special alloy material 38CrMoAl via special process. The screw can be freely assembled according to the raw material and products. It has strong intensity, good wear resistance and prolonged service life. The cylinder is made of special alloy 40Cr. The cylinder is equipped with water injection device, fully automatic heating and cyclic cooling system which can realize accurate temperature controlling.Motor ABB electric devices Schneider electric devices Distribution box Barrel Screw Italian Baltur burner Omron temperature control instrument

Quality inspection

All the equipment should be tested before delivery. For the core components of the extruder, the distribution box, Saixin has a professional testing platform which can ensure that each set of distribution box will continuously running for 48h before delivery to make sure its stability.